Liquid Molding Monthly

How to Choose the Right Epoxy Coating for Your Industrial Flooring Needs

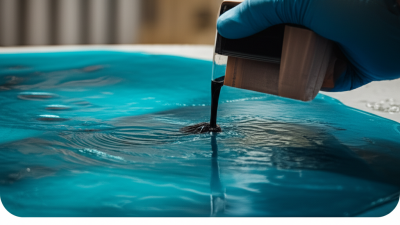

In the realm of industrial flooring, the selection of the

appropriate epoxy coating is crucial for ensuring durability, safety, and performance. According

to a recent report by MarketsandMarkets, the global epoxy resins market is projected

to reach USD 12.5 billion by 2026, underscoring the rising

demand for high-quality coatings in various industries including manufacturing,

automotive, and electronics. Epoxy coatings are favored for their

robust adhesion properties, chemical resistance, and the ability to withstand heavy foot and

vehicle traffic.

In the realm of industrial flooring, the selection of the

appropriate epoxy coating is crucial for ensuring durability, safety, and performance. According

to a recent report by MarketsandMarkets, the global epoxy resins market is projected

to reach USD 12.5 billion by 2026, underscoring the rising

demand for high-quality coatings in various industries including manufacturing,

automotive, and electronics. Epoxy coatings are favored for their

robust adhesion properties, chemical resistance, and the ability to withstand heavy foot and

vehicle traffic.

However, with a multitude of options available, it is vital to understand the specific requirements of your facility, such as traffic load, environmental conditions, and aesthetic preferences. This guide aims to provide insights into the decision-making process of choosing the right epoxy coating to meet your industrial flooring needs effectively.

Understanding Different Types of Epoxy Coatings: A Comprehensive Overview of Options

When considering the right epoxy coating for industrial flooring, it’s essential to understand the various types available and their specific applications. Epoxy coatings can range from those offering superior durability and chemical resistance to ones designed for enhanced slip resistance. Recent studies in surface engineering have shown that epoxy coatings boast significantly improved slip resistance compared to traditional polymer and acrylic coatings, making them ideal for high-traffic industrial environments (source: Industry Report on Floor Coating Performance).

Additionally, advancements in epoxy formulations have led to sustainable options that reduce environmental impact. For instance, replacing PFAS modifiers with greener alternatives can mitigate potential hazards associated with conventional chemical coatings. Reports indicate that these passive ice-phobic coatings not only perform efficiently but also align with increasing industry demands for sustainability, thus appealing to companies seeking to enhance their environmental policies while maintaining safety and effectiveness in their flooring solutions.

How to Choose the Right Epoxy Coating for Your Industrial Flooring Needs

| Epoxy Coating Type | Durability | Chemical Resistance | Installation Complexity | Typical Applications |

|---|---|---|---|---|

| Solid Epoxy | High | Excellent | Moderate | Warehouses, factories |

| Epoxy Novolac | Very High | Exceptional | High | Chemical processing, refineries |

| Self-Leveling Epoxy | High | Good | Moderate | Retail, showrooms |

| Epoxy Floor Paint | Moderate | Fair | Low | Commercial garages, small workshops |

| Conductive Epoxy | High | Good | High | Electronics manufacturing, medical facilities |

Key Factors to Consider When Assessing Industrial Foot Traffic and Wear Resistance

When selecting the right epoxy coating for industrial flooring, evaluating foot traffic and wear resistance is crucial. High-traffic areas demand more durable coatings, as they will experience significant wear over time. Identify the volume and type of traffic—whether it's light, moderate, or heavy—as this will inform your choice of epoxy. Heavy loads and frequent movement require coatings that can withstand impacts and abrasions while maintaining their aesthetic appeal.

**Tips:** Consider the specific application environment. For instance, if the flooring will be exposed to chemicals or harsh cleaning regimes, opt for a chemical-resistant epoxy formulation. Additionally, look for coatings with high tensile strength to ensure they can handle heavy loads without cracking.

Another factor to consider is the curing time of the epoxy. Faster curing times may be beneficial in operations where downtime needs to be minimized. However, ensure that the chosen product still provides optimal wear and tear resistance to meet your operational demands. Prioritize products that offer both quick installation and long-lasting performance for a successful flooring solution.

Evaluating Chemical Resistance Ratings for Epoxy: Essential for Specific Industries

When selecting an epoxy coating for industrial flooring, evaluating the chemical resistance ratings is crucial, especially for industries that handle harsh substances. According to a 2022 report from the Industrial Coatings Association, certain epoxy formulations can withstand exposure to a variety of chemicals, including acids, alkalis, and solvents, making them indispensable in sectors like automotive manufacturing, food and beverage processing, and pharmaceuticals. For instance, a high-performance epoxy coating rated for chemical resistance can tolerate environments with pH levels between 2 and 12, providing necessary durability where spills and chemical exposure are commonplace.

Moreover, the effectiveness of an epoxy’s chemical resistance varies significantly based on its specific formulation. A 2023 study from the Flooring Solutions Institute highlighted that coatings enriched with specialized additives can enhance resistance to specific chemicals, such as petroleum products or cleaning agents, by more than 50%, thereby extending the lifespan of industrial flooring. Industries must assess these ratings not only to ensure compliance with safety standards but also to minimize downtime and maintenance costs associated with flooring failures. Therefore, choosing the appropriate epoxy coating should be informed by rigorous analysis of chemical resistance ratings tailored to the operational environment.

Cost Analysis: Budgeting for Installation and Long-Term Maintenance of Epoxy Flooring

When considering the installation of epoxy flooring, a detailed cost analysis is essential for budgeting effectively. The initial costs often include the materials, labor charges, and any preparatory work required to ensure the substrate is suitable for epoxy application. Prices can vary widely depending on the quality of epoxy selected, with high-performance options typically costing more upfront. It is crucial to factor in these initial expenses when planning your budget, as opting for lower-quality materials can lead to increased repair costs down the line.

Long-term maintenance is another critical component of the overall expense. While epoxy floors are known for their durability and low maintenance requirements, periodic upkeep is still necessary to preserve their integrity. This might include re-sealing the surface or addressing minor wear and tear. Understanding these potential future costs is vital for a comprehensive financial overview, helping businesses make informed decisions that align with their operational needs and fiscal constraints. By considering both initial and ongoing costs, you can ensure a balanced approach to your epoxy flooring investment.

Cost Analysis: Budgeting for Installation and Long-Term Maintenance of Epoxy Flooring

Environmental Impact and Sustainability: Choosing Eco-Friendly Epoxy Solutions for Industry

When selecting an epoxy coating for industrial flooring, sustainability and environmental impact must be at the forefront of the decision-making process. Recent trends indicate a growing preference for eco-friendly solutions that minimize harm to the environment. Notably, the epoxy resins market is projected to experience significant growth over the coming years, driven by innovations that focus on sustainable practices. Research highlights that new resin compositions are being analyzed for their environmental performance in various applications, including those requiring cryogenic conditions, underscoring a shift towards more responsible production methods.

Furthermore, initiatives like the development of plant-based and biodegradable materials are gaining traction within the broader context of sustainable manufacturing. For instance, plant-based packaging solutions demonstrate effective utilization of renewable resources, addressing consumer demand for environmentally-friendly products. Analysis of epoxy coatings, especially those that enhance durability while reducing ecological footprints, is essential — with the industry looking towards solutions that align with the principles of the circular economy. As companies innovate, the launch of sustainable epoxy products signals a new era wherein performance and environmental responsibility go hand in hand, fulfilling industrial needs without compromising the health of our planet.

Related Posts

-

Unleashing the Power of Best Resin Coating in Global Manufacturing Revolution

-

7 Compelling Reasons to Choose Polyurethane Casting for Your Next Project

-

Ultimate Guide to Choosing the Best Industrial Epoxy Resin for Your Projects

-

How to Achieve Stunning Results with Clear Epoxy Resin in Your DIY Projects

-

How to Maximize the Benefits of Polymer Performance in Your Industry

-

Unveiling Opportunities at the 137th Canton Fair for Polymer Equipment Global Buyers

100% Mercury Free

All of Hapco's formulations are completely free of Mercury.

50 Year Track Record

Hapco has been in business for over 50 years!

*NOTICE* Hapco will be will be closed on Monday, May 26th, in observance of Memorial Day. |

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |