The Titan Disaster

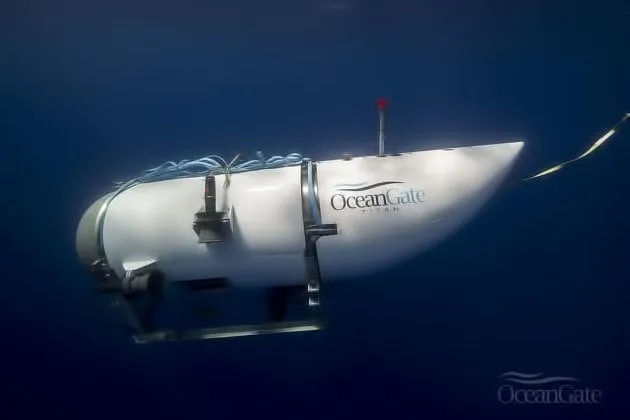

While carbon fiber is celebrated for its high tensile strength and reduced weight, which is advantageous in many applications, questions were raised about its performance and reliability under the extreme pressures of deep-sea conditions.

The Disaster: What Happened?

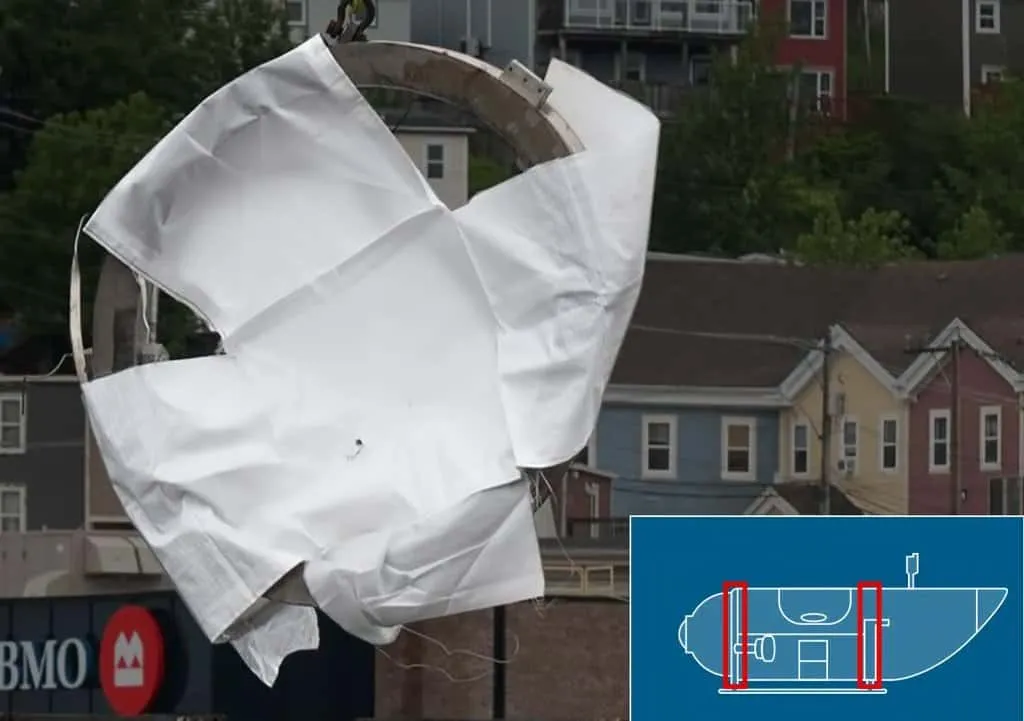

During its expedition to the Titanic wreck, the Titan succumbed to the relentless pressure of the deep ocean. Its implosion, resulting in the loss of all onboard, pointed to a catastrophic failure in its structural integrity.

Focusing on the Hull’s Failure

The core of the disaster lies in the failure of the Titan’s spun carbon fiber hull. Carbon fiber, known for its strength and lightweight properties, may not have been ideally suited to withstand the immense pressures at such depths.

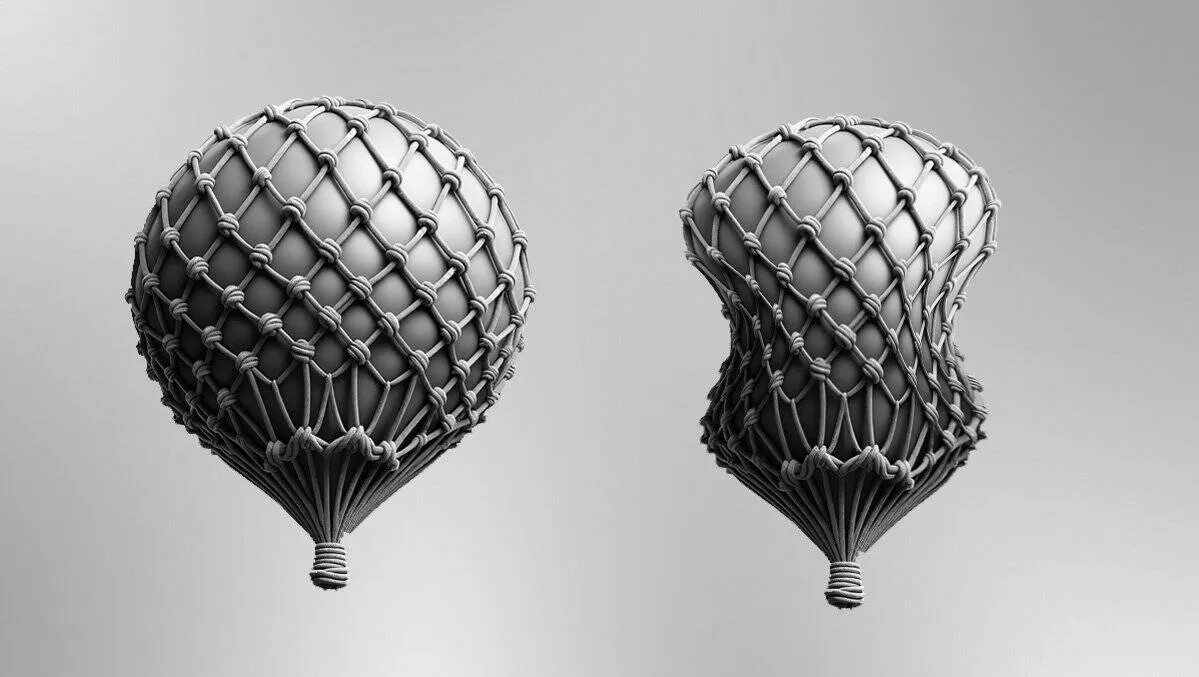

Spun carbon fiber containers are more resistant to internal pressure than external pressure, making them ideal for storing compressed air. However, their use in transporting passengers to depths of 2.5 miles under external pressures of 6500 psi has tragically highlighted their limitations. Imagine carbon fiber as a balloon encased in a net: the net’s strength prevents the balloon from over-expanding, similar to how carbon fiber’s high tensile strength copes with internal pressure. However, when pressure is applied inwards, the net provides less support, placing more stress on the balloon’s surface and increasing the risk of damage.

Spun carbon fiber containers are more resistant to internal pressure than external pressure, making them ideal for storing compressed air. However, their use in transporting passengers to depths of 2.5 miles under external pressures of 6500 psi has tragically highlighted their limitations. Imagine carbon fiber as a balloon encased in a net: the net’s strength prevents the balloon from over-expanding, similar to how carbon fiber’s high tensile strength copes with internal pressure. However, when pressure is applied inwards, the net provides less support, placing more stress on the balloon’s surface and increasing the risk of damage.

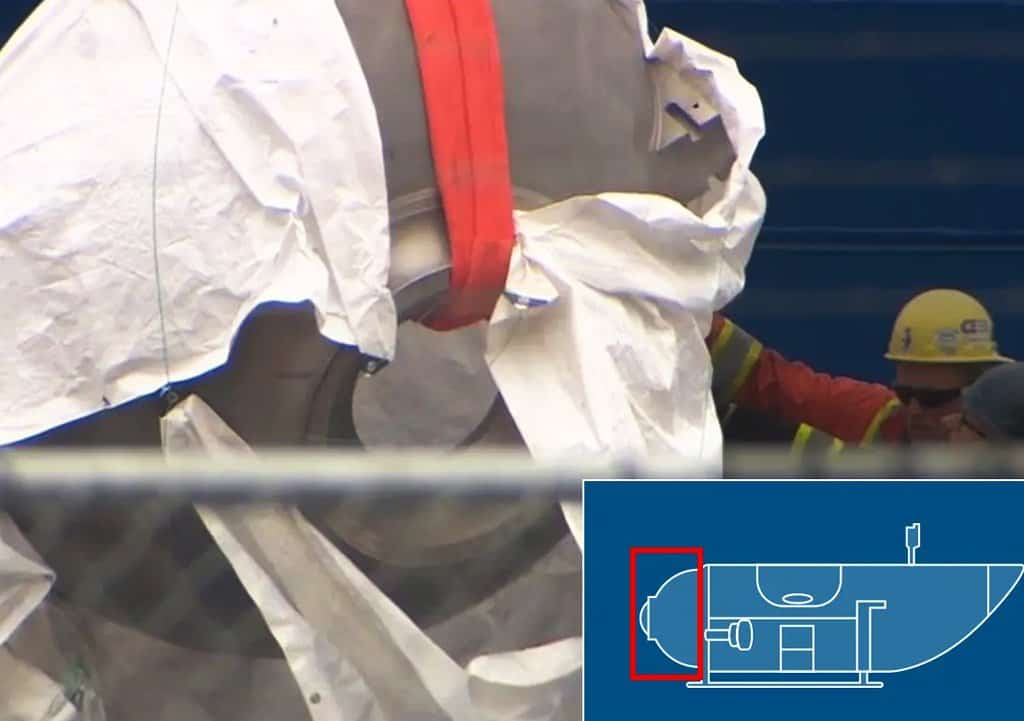

Delamination in carbon fiber, which results from stress, doesn’t lead to immediate failures; instead, it gradually accumulates damage over time. This explains why the Titan could endure multiple dives before ultimately failing. Another important consideration is how the carbon fiber was laid. Criss-crossing the layers every other pass is how oxygen tanks and other pressure vessels are typically manufactured; however, from the videos of the hull’s manufacture, it appears the carbon fiber was laid in one direction.

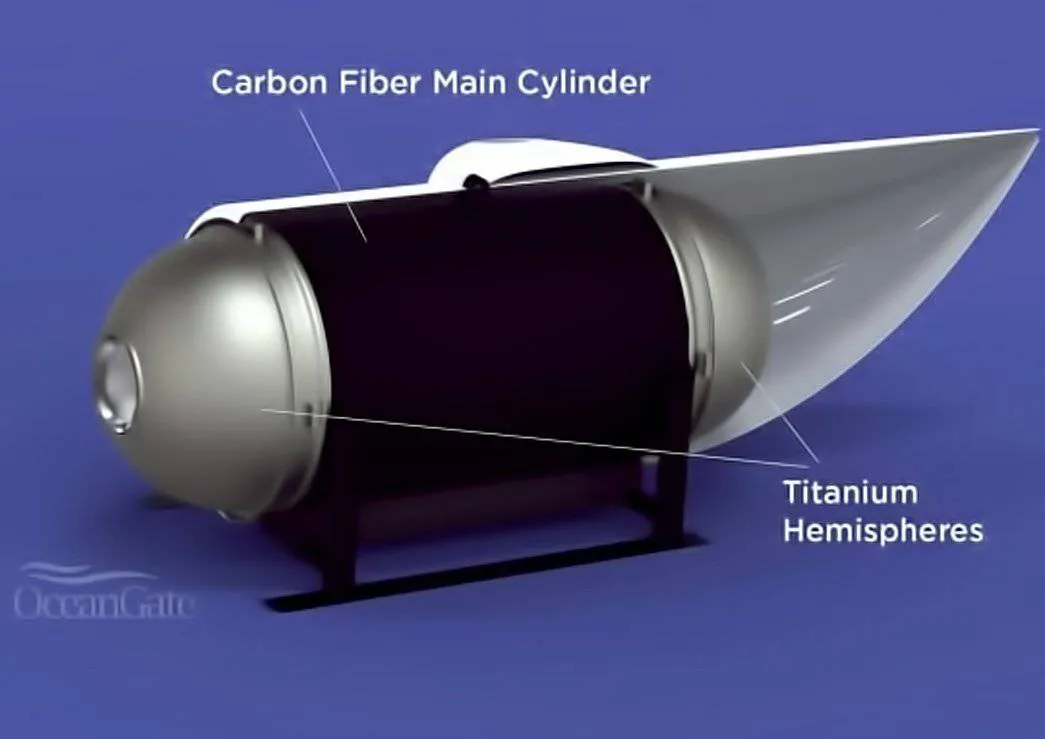

The Titanium Caps: A Potential Catalyst

Integrating titanium caps with the carbon fiber hull was a critical design choice. Titanium and carbon fiber have considerably different linear expansion coefficients. Under the extreme conditions of deep-sea exploration, these differences could have led to structural weaknesses, exacerbating the risk of implosion.

Titanium can withstand repeated stress over a long period without significant degradation. Carbon fiber also has excellent fatigue properties, but these can be affected by the type of resin used, the process of laying the fibers, and the type of stress (e.g. continuous, intermittent). Many experts have noted that the design should have used a spherical shape instead of an oblong, as the forces surrounding it would’ve been equal.

Analyzing Material Compatibility

The combination of carbon fiber and titanium in Titan’s construction deserves a more in-depth analysis. The end caps were bonded to the carbon fiber hulls with epoxy resin, another differing expansion rate and potential failure point.The thermal expansion mismatch between these materials in average deep-sea conditions may have resulted in delamination of the epoxy adhesive used at the junctions, potentially contributing to the hull’s catastrophic failure.

Lessons Learned and Industry Implications

The Titan tragedy highlights the importance of thoroughly understanding material properties and interactions in engineering designs, especially in extreme environments. It prompts a reevaluation of material selection and compatibility in submersible vessel construction.

In preventing disasters like the Titan implosion, rigorous adherence to best practices in material selection is paramount:

- It’s essential to conduct a thorough material analysis, which involves understanding the physical, chemical, and environmental properties of the materials under consideration. Additionally, you should complete real-world testing under conditions that simulate actual usage scenarios.

- Always maintain compliance with industry standards and regulations; these standards are often based on historical data and past incidents, offering valuable guidelines for safe material usage. Collaboration with experienced engineers and specialists is also crucial, as their expertise can provide insights into various applications and material behaviors that take time to become apparent.

- Continuous monitoring and reassessment of materials throughout the lifecycle of a project are necessary, as new information or changing conditions can impact material suitability.

- Maintain comprehensive documentation of material selection processes to aid in accountability and continuous improvement, ensuring the application of lessons learned in future projects.

Implementing these best practices can significantly mitigate the risks associated with improper material selection, safeguard capital investments, and, more importantly, keep people safe when their lives depend on it.

Final Thoughts

The Titan submarine disaster is a strong reminder of the complexities involved in material engineering. As we push the boundaries of exploration, the fusion of innovation and material science becomes crucial for safety and success. It’s vital to balance human ambition with respect for Mother Nature’s forces, ensuring our technological strides harmonize with the natural world’s complexities and power.

Fun Fact: Did you know that the Romans were masters of material selection in ancient engineering? One of their most impressive feats was the creation of Roman concrete, also known as opus caementicium. This material was so well-engineered that many Roman structures, like the Pantheon and the aqueducts, have withstood the test of time for over two millennia. Their secret? The incorporation of volcanic ash, which not only made the concrete stronger but also enabled it to set underwater, revolutionizing marine construction.

Fun Fact: Did you know that the Romans were masters of material selection in ancient engineering? One of their most impressive feats was the creation of Roman concrete, also known as opus caementicium. This material was so well-engineered that many Roman structures, like the Pantheon and the aqueducts, have withstood the test of time for over two millennia. Their secret? The incorporation of volcanic ash, which not only made the concrete stronger but also enabled it to set underwater, revolutionizing marine construction.