Titan Submersible Update

The Disaster and Its Aftermath

In our previous article, we discussed the tragic June 18, 2023 implosion of OceanGate’s Titan submersible that claimed the lives of five individuals during their descent to the Titanic wreckage. We explored how improper material selection can lead to catastrophic failures and emphasized the critical importance of choosing the right materials in engineering applications.

This follow-up analysis examines deeper technical aspects of the disaster. While initial reports focused on catastrophic hull failure, recent forensic analyses have uncovered a more nuanced contributing factor: the impact of thermal expansion mismatches between key materials.

Disclaimer: Hapco wishes to clarify that it has no affiliation, association, or partnership with OceanGate or its vendors. Any references to OceanGate or related entities in our content are for informational purposes only and do not imply any collaboration or connection between Hapco and these organizations.

Understanding the Material Mismatch

What caused the Titan submersible to fail so catastrophically? Many pointed to the carbon fiber hull, but deeper forensic investigation has highlighted an often-overlooked issue: the difference in how materials expand and contract with temperature changes.

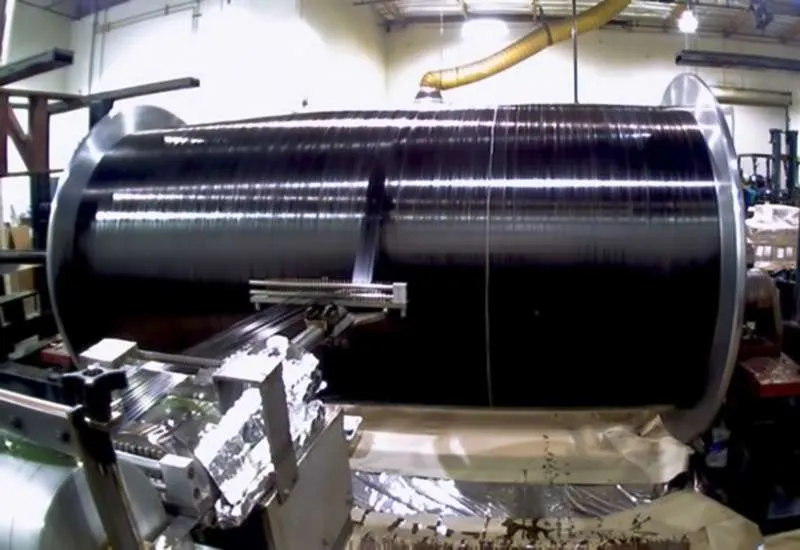

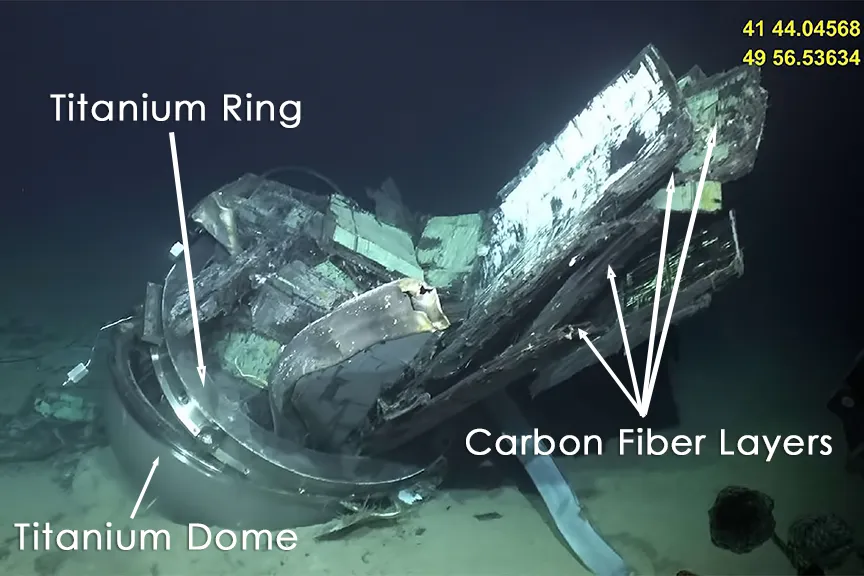

Manufacturing imperfections in the carbon fiber hull, such as voids and delamination, contributed to its vulnerability. However, a more subtle yet equally critical factor was the substantial difference in coefficients of thermal expansion (CTE) between the carbon fiber hull and the titanium end caps.

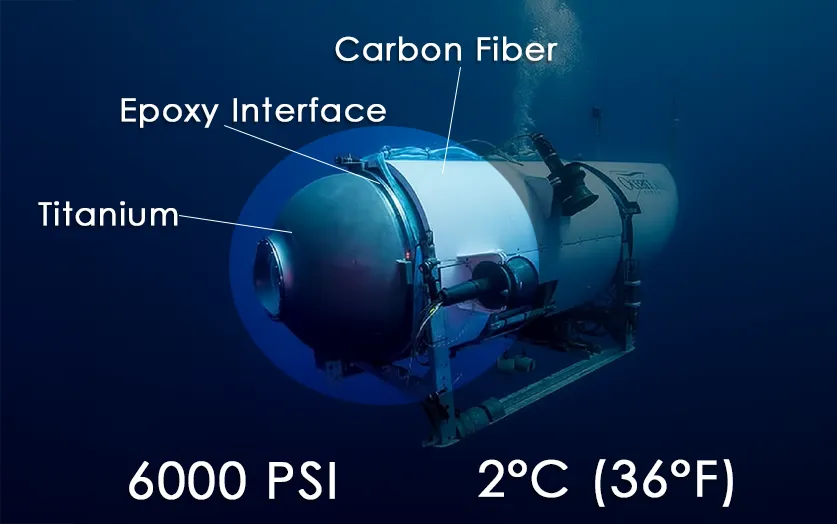

Titanium expands and contracts at a rate of approximately 8.6 × 10^-6 per degree Celsius, while carbon fiber composites, depending on fiber orientation, expand at a much lower rate (near zero to 2 × 10^-6/°C). This difference in expansion rates, known as the coefficient of thermal expansion (CTE), became a key failure point.

As Titan moved from warm surface waters (approximately 20°C) to the near-freezing depths (around 2°C) of the Titanic site, the titanium end caps contracted significantly more than the carbon fiber hull. This differential contraction created additional stress precisely at the junction between these materials, particularly at the epoxy bond, which investigators now believe was a likely failure point.

The Hidden Danger of Cyclic Thermal Stresses

Beyond immediate structural concerns, another key issue emerges: how repeated exposure to thermal cycles progressively weakened the Titan’s structural integrity.

Materials engineers now suggest that repeated dive cycles caused cumulative damage through thermal cycling. Each descent-ascent sequence subjected the junction between these dissimilar materials to significant thermal stress, potentially weakening the bonding over time.

“The engineering challenge was not just managing immediate pressure,” explains Dr. Samantha Rodríguez from the Maritime Materials Institute. “It was accounting for how different materials respond to simultaneous pressure and temperature changes over multiple cycles. Each thermal cycle potentially degraded the critical bond strength at the titanium-carbon interface.”

Deep-Sea Thermal Management Complexities

The investigation highlights the complex interplay of thermal factors in deep-sea vessels. Unlike shallow-water applications, deep submergence vehicles must account for multiple thermal considerations:

- Dramatic ambient temperature changes (up to 18°C difference)

- Temperature gradients across hull thickness

- Thermal interactions between mechanical systems and structural components

- Heat generated by internal electronics and life support systems

- Microcycles caused by currents and thermal layers in the water column

Computer modeling of Titan’s thermal profile suggests that temperature differentials within the structure itself may have exceeded design parameters, particularly at the critical titanium-carbon fiber interface points.

Industry Response: Fundamental Changes in Material Selection

In response to these findings, the maritime industry has developed new approaches to submersible design:

- Material Matching: Engineers are prioritizing materials with compatible thermal expansion properties to reduce stress at junctions.

- Gradient Interfaces: Some researchers are exploring the use of transitional materials at connection points, which gradually shift thermal expansion properties between dissimilar materials.

- Advanced Modeling: New simulation techniques now track how materials behave over thousands of thermal cycles, ensuring durability over time.

- Innovative Composite Layering: Engineers are refining carbon fiber layups and resin systems to minimize thermal expansion differences.

- Real-Time Monitoring: Emerging technologies include sensors that detect and analyze expansion-related stresses in real time, preventing unnoticed structural degradation.

Several research institutions have launched initiatives specifically addressing CTE challenges in deep-sea applications. The Woods Hole Oceanographic Institution has established a dedicated laboratory for testing material interfaces under combined pressure and thermal cycling conditions.

The Path Forward: Integrating Thermal Considerations

The most promising developments incorporate thermal management from the earliest design stages.

“We are seeing a fundamental shift in how engineers approach deep submergence vehicle design,” notes Martin Weissman, former naval architect and senior consultant at Deep Ocean Safety Systems. “Rather than treating pressure as the sole primary concern, there is recognition that thermal factors, particularly at material interfaces, require equal consideration throughout the design, manufacturing, and operational life of these vessels.”

Recent submersible designs have incorporated features like thermally-managed transition zones between different materials, active thermal monitoring systems, and adaptive bonding agents designed to accommodate slight movements at material junctions.

Learning from Tragedy: A Call for Industry Standards

The Titan disaster serves as a sobering reminder of the complexities of deep-sea engineering. However, by applying lessons from this tragedy through smarter materials, rigorous thermal modeling, and better industry standards, we can build safer, more resilient vehicles for future exploration.

While no single factor was likely responsible for the tragedy, the investigation has highlighted how seemingly secondary considerations like thermal expansion can become primary failure modes under extreme conditions. This knowledge must be incorporated into formal industry standards and testing protocols.

The pursuit of oceanic discovery should continue, but always with the safety of human passengers as the main consideration. Only through rigorous engineering discipline, comprehensive testing, and transparent oversight can we ensure that future missions to the ocean depths proceed without risking preventable tragedies.