Liquid Molding Monthly

How to Maximize the Benefits of Polymer Performance in Your Industry

As industries continue to evolve, the significance of Polymer Performance has never been more pronounced. According to a report by MarketsandMarkets, the global polymer market is projected to reach USD 1,302.4 billion by 2024, growing at a CAGR of 5.3%. This growth underscores the critical role polymers play across various sectors, from automotive and aerospace to healthcare and construction. By effectively leveraging Polymer Performance, companies can enhance product durability, reduce manufacturing costs, and meet stringent regulatory standards. Additionally, advancements in polymer composites and smart polymers are creating new opportunities for innovation, enabling industries to address modern challenges such as sustainability and resource efficiency. In this blog, we will explore strategies to maximize the benefits of Polymer Performance, ensuring that your operations not only keep pace with industry standards but also set new benchmarks for excellence.

As industries continue to evolve, the significance of Polymer Performance has never been more pronounced. According to a report by MarketsandMarkets, the global polymer market is projected to reach USD 1,302.4 billion by 2024, growing at a CAGR of 5.3%. This growth underscores the critical role polymers play across various sectors, from automotive and aerospace to healthcare and construction. By effectively leveraging Polymer Performance, companies can enhance product durability, reduce manufacturing costs, and meet stringent regulatory standards. Additionally, advancements in polymer composites and smart polymers are creating new opportunities for innovation, enabling industries to address modern challenges such as sustainability and resource efficiency. In this blog, we will explore strategies to maximize the benefits of Polymer Performance, ensuring that your operations not only keep pace with industry standards but also set new benchmarks for excellence.

Understanding Polymer Performance and Its Importance in Various Industries

Polymers are ubiquitous in modern industries, playing a crucial role in everything from manufacturing to healthcare. Understanding polymer performance is essential for enhancing product functionality and operational efficiency. In various sectors, including automotive, packaging, and electronics, the properties of polymers, such as strength, flexibility, and resistance to chemicals, directly influence the final application’s success. For instance, automotive manufacturers rely on high-performance polymers to reduce weight and improve fuel efficiency, while the packaging industry utilizes polymers that maintain product freshness and extend shelf life.

In addition to mechanical properties, thermal stability and environmental resistance of polymers are vital in industries such as construction and aerospace. Advanced polymer formulations can withstand extreme temperatures and harsh conditions, ensuring safety and longevity in demanding applications. By focusing on the specific needs of an industry and selecting the right polymer materials, companies can optimize performance, reduce costs, and improve sustainability. Collaborating with experts in polymer science can also lead to the development of innovative solutions that push the boundaries of what these materials can achieve, ultimately maximizing their benefits across various industrial applications.

Maximizing Polymer Performance Across Industries

Key Properties of Polymers That Impact Performance Metrics

When considering the key properties of polymers that impact performance metrics, it's essential to focus on both mechanical and functional attributes. Recent studies emphasize the importance of optimizing parameters such as synthesis techniques and processing conditions to enhance polymer capabilities. For instance, optimizing the direct condensation and ring-opening polymerization of polylactic acid (PLA) can significantly improve its multifunctional performance. By leveraging advanced processing methods, such as electrospinning, researchers have shown that parameters like applied voltage and flow rate can be crucial for developing high-quality PVA/PLA nanofibers suitable for biomedical applications.

Another critical aspect is the development of sustainable polymer composites. Recent innovations have demonstrated that infusing small amine molecules and polyamines into mesoporous substrates can enhance CO2 sorption capacities, making them promising materials for environmental applications. Moreover, the settings used in 3D printing short carbon fiber reinforced polymers (CFRP) significantly impact the mechanical properties and failure performance of these composites, illustrating how processing conditions directly correlate with end-use effectiveness. By continuously optimizing these key properties and performance metrics, industries can unlock the full potential of polymers across various applications, leading to more sustainable and functional materials.

How to Maximize the Benefits of Polymer Performance in Your Industry - Key Properties of Polymers That Impact Performance Metrics

| Property | Impact on Performance | Industry Application |

|---|---|---|

| Tensile Strength | Determines the material's ability to withstand pulling forces. | Automotive, Aerospace |

| Flexural Modulus | Indicates rigidity and resistance to bending. | Construction, Consumer Goods |

| Impact Resistance | Measures the energy absorption before failure. | Packaging, Electronics |

| Thermal Stability | Resilience to heat exposure during processing and use. | Medical, Aerospace |

| Chemical Resistance | Capability to withstand various chemical exposures. | Chemical Processing, Automotive |

Techniques to Enhance Polymer Performance in Manufacturing Processes

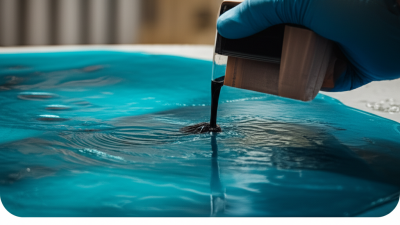

When it comes to enhancing polymer performance in manufacturing processes, several techniques can significantly elevate the efficiency and quality of your products. One effective method is the optimization of processing parameters, such as temperature, pressure, and cooling rates. By fine-tuning these variables, manufacturers can improve the mechanical properties and durability of the polymers used, resulting in stronger and more reliable end products. For instance, adjusting the cooling rates during molding can help reduce defects and improve the uniformity of the material.

When it comes to enhancing polymer performance in manufacturing processes, several techniques can significantly elevate the efficiency and quality of your products. One effective method is the optimization of processing parameters, such as temperature, pressure, and cooling rates. By fine-tuning these variables, manufacturers can improve the mechanical properties and durability of the polymers used, resulting in stronger and more reliable end products. For instance, adjusting the cooling rates during molding can help reduce defects and improve the uniformity of the material.

Another technique to maximize polymer performance is the incorporation of additives and fillers. These substances can enhance specific properties such as tensile strength, heat resistance, and flexibility. For example, adding glass fibers to a polymer matrix can significantly increase its rigidity and impact resistance, making it suitable for demanding applications. Moreover, utilizing advanced compounding techniques ensures a homogeneous distribution of these additives, further improving the overall performance of the polymer during its application.

Lastly, adopting innovative polymer blends can lead to exceptional performance enhancements. By combining two or more polymers, manufacturers can create materials that capitalize on the best characteristics of each component. This approach not only enhances performance metrics like toughness and thermal stability but also allows for more sustainable manufacturing practices. The strategic selection and synthesis of polymer blends offer endless possibilities for innovation in various industries, from automotive to consumer goods.

Case Studies: Successful Implementation of Polymer Innovations

The implementation of polymer innovations in various industries has yielded remarkable results, as demonstrated by several case studies. For instance, in the automotive sector, a recent report by MarketsandMarkets indicates that the use of lightweight polymers has led to an average weight reduction of 10-30% in vehicles. This reduction not only enhances fuel efficiency but also improves overall performance, showcasing the direct benefits of polymer applications in manufacturing processes.

In the packaging industry, advancements in polymer technologies have transformed how companies approach sustainability. A study by Smithers Pira highlights that the global biodegradable plastics market is expected to reach $16.6 billion by 2024, largely driven by the demand for eco-friendly packaging solutions. Companies like Coca-Cola have adopted plant-based PET polymers in their bottling processes, resulting in a significant reduction of their carbon footprint. Such initiatives exemplify how integrating innovative polymer solutions can align with both environmental goals and business strategies, ultimately maximizing benefits across the supply chain.

Future Trends in Polymer Technology and Their Implications for Industries

As we venture into the future of polymer technology, industries must stay ahead of emerging trends to fully exploit the capabilities of these versatile materials. One significant development is the rise of bio-based and biodegradable polymers. As sustainability becomes a priority for consumers and regulatory bodies alike, industries will be compelled to innovate towards materials that minimize environmental impact. These newer polymers can reduce carbon footprints and offer greater recycling potential, paving the way for more sustainable manufacturing processes.

Additionally, the integration of advanced technologies such as artificial intelligence and machine learning in polymer production is expected to revolutionize the industry. These technologies allow for better predictive modeling, enabling manufacturers to optimize production processes and enhance material performance. By leveraging data analytics, companies can also improve quality control and ensure that polymers meet precise specifications, ultimately leading to superior products. As the landscape of polymer technology continues to evolve, staying informed and adaptable will be crucial for industries aiming to harness the full potential of these innovative materials.

Related Posts

-

Unlocking the Advantages of High Performance Polymers for Enhanced Durability and Efficiency

-

How to Navigate Import and Export Certifications for the Best Casting Materials Globally

-

Emerging Trends in Industrial Epoxy Resin Technology for 2025 and Essential Procurement Checklist

-

Unleashing the Power of Best Resin Coating in Global Manufacturing Revolution

-

Ultimate Guide to Choosing the Best Industrial Epoxy Resin for Your Projects

-

Discover Premium Casting Epoxy Resin: China's Quality Manufacturing at Your Service!

100% Mercury Free

All of Hapco's formulations are completely free of Mercury.

50 Year Track Record

Hapco has been in business for over 50 years!

*NOTICE* Hapco will be will be closed on Monday, May 26th, in observance of Memorial Day. |

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |