Liquid Molding Monthly

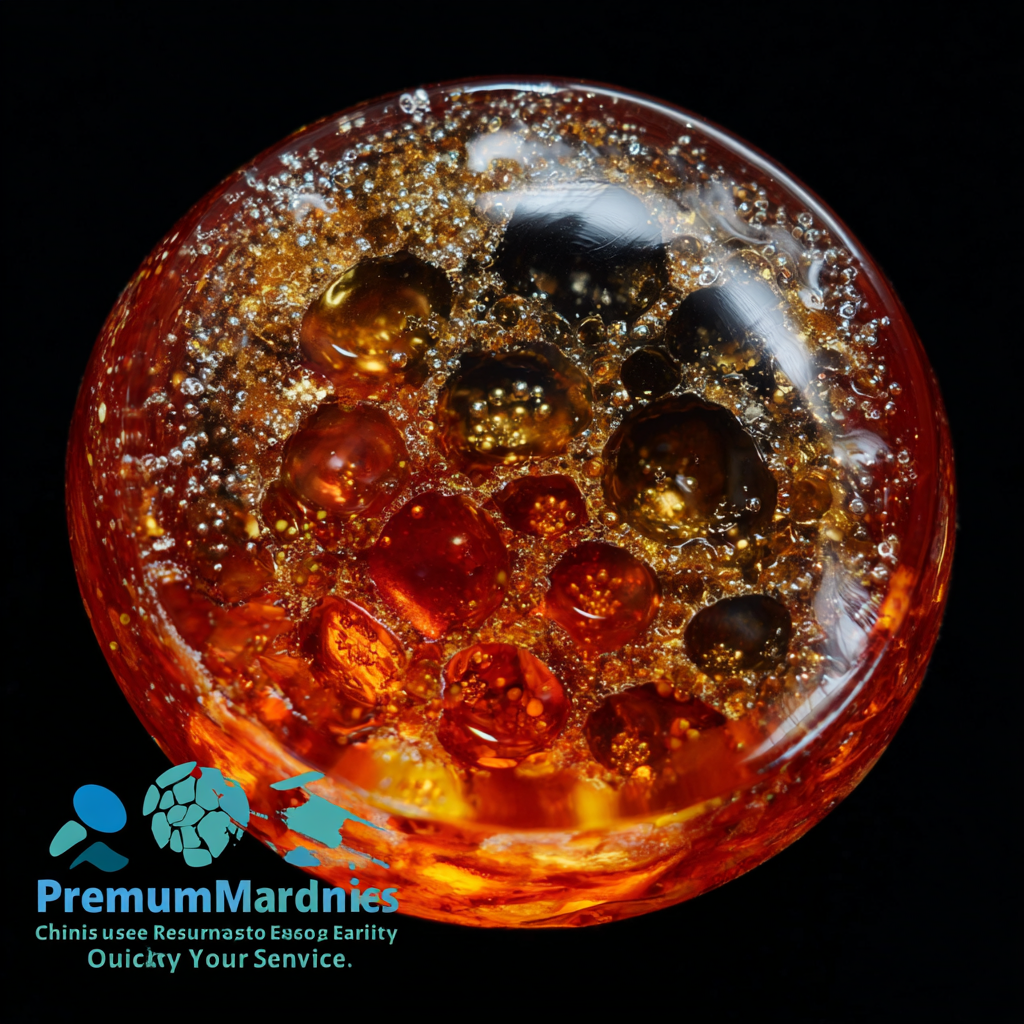

Discover Premium Casting Epoxy Resin: China's Quality Manufacturing at Your Service!

In today's rapidly evolving craft and manufacturing landscape, the demand for high-quality materials is at an all-time high, particularly in the realm of creative projects and industrial applications. One such material that has gained immense popularity is Casting Epoxy Resin, known for its versatility, durability, and aesthetic appeal. These properties make it a favorite among artists, designers, and manufacturers alike. As we delve into the world of Casting Epoxy Resin, we will explore how China's commitment to quality manufacturing plays a pivotal role in meeting global demand. This blog will not only highlight the superior features and applications of Casting Epoxy Resin but also emphasize the importance of sourcing from reputable Chinese manufacturers who prioritize excellence and innovation. Join us on this journey to discover how you can elevate your projects with premium Casting Epoxy Resin, crafted meticulously to serve your creative and industrial needs.

The Rise of Premium Casting Epoxy Resin in China's Manufacturing Landscape

The surging demand for premium casting epoxy resin in China's manufacturing landscape is reshaping the market dynamics significantly. According to a recent market research report by ResearchAndMarkets, the global epoxy resin market is expected to reach USD 15 billion by 2025, with a substantial portion of that growth attributed to advancements in Chinese manufacturing capabilities. This rise is driven by innovations in product formulations, enhancing durability, and reducing environmental impact, leading to increased adoption across various industries, from automotive to construction.

Notably, China has established itself as a key player in the production of high-quality epoxy resins. The China National Chemical Corporation reported that domestic manufacturers have increased their output of premium-grade epoxy resins by over 25% annually since 2020. This growth is supported by substantial investments in research and development, enabling companies to produce resins that offer superior performance characteristics, such as superior adhesion, excellent UV resistance, and enhanced thermal stability. Furthermore, meeting international quality standards has positioned China favorably in the global market, enabling exporters to cater to the growing demand for premium materials worldwide.

Key Industry Statistics: China's Export Growth in Epoxy Resin Production

China has emerged as a leader in the global epoxy resin market, showcasing remarkable growth in export production. In recent years, the country has witnessed a steady increase in demand for high-quality casting epoxy resins, driven by their versatility in various applications, including construction, automotive, and art industries. According to key industry statistics, China’s epoxy resin exports surged by over 20% last year, reflecting the international preference for their superior manufacturing standards and innovative approaches.

For those looking to utilize casting epoxy resin, it's essential to choose products from reputable manufacturers who adhere to stringent quality control measures. Always check for industry certifications and reviews to ensure you're investing in top-tier materials. Additionally, consider the specific properties you require—such as curing time and UV resistance—tailored to your project's needs.

When working with epoxy resins, proper handling and safety measures are crucial. Ensure that you are working in a well-ventilated space and wear appropriate protective gear. Understanding the mixing ratios and cure times can dramatically affect your results, so take the time to follow the guidelines provided by the manufacturer for optimal outcomes.

Discover Premium Casting Epoxy Resin: China's Quality Manufacturing at Your Service!

| Year | Export Volume (tons) | Export Value (USD million) | Top Export Destinations | Growth Rate (%) |

|---|---|---|---|---|

| 2018 | 50,000 | 150 | USA, Germany, Japan | 10 |

| 2019 | 55,000 | 165 | USA, South Korea, Netherlands | 10 |

| 2020 | 60,000 | 180 | USA, Australia, UK | 10 |

| 2021 | 70,000 | 210 | Canada, UK, India | 16.67 |

| 2022 | 80,000 | 250 | Germany, USA, Spain | 33.33 |

| 2023 | 90,000 | 300 | France, Netherlands, Japan | 25 |

Quality Control Measures: Ensuring Excellence in Manufacturing Processes

In the realm of premium casting epoxy resin production, stringent quality control measures are paramount to ensure the excellence of manufacturing processes. According to a recent report from the Global Resin Market Analysis, the demand for high-quality epoxy resin is projected to grow at a CAGR of 6.5% through 2028. This surge underscores the necessity for manufacturers to implement rigorous quality assurance protocols to meet evolving industry standards and consumer expectations.

To achieve this, manufacturers in China are investing heavily in advanced quality control systems. This includes employing statistical process control (SPC) techniques and conducting regular material testing, which allows for real-time monitoring of production processes. Notably, 94% of leading resin manufacturers have adopted ISO 9001 quality management systems to streamline operations and enhance product reliability. These measures not only ensure consistency in product quality but also reduce defect rates, fostering greater trust among clients and end-users alike in the competitive global market. By prioritizing quality, Chinese manufacturers are setting benchmarks that resonate well with international standards.

Innovative Applications of Epoxy Resin Across Various Sectors

Epoxy resin is revolutionizing various sectors with its versatility and durability. According to a report by Grand View Research, the global epoxy resin market size was valued at approximately $9.06 billion in 2019 and is projected to grow at a CAGR of 6.9% from 2020 to 2027. This remarkable growth reflects the increasing demand for epoxy resin in industries such as construction, automotive, and electronics. The material's excellent adhesion, chemical resistance, and thermal stability make it an ideal choice for a wide range of applications, including adhesives, coatings, and composites.

In the construction sector, for instance, epoxy resin is extensively used for flooring systems that not only enhance aesthetic appeal but also provide long-lasting protection against wear and chemical damage. A study from Mordor Intelligence indicates that the construction segment accounted for over 30% of the epoxy resin market share in 2020, showcasing its critical role in infrastructure development. Similarly, in the automotive industry, epoxy resins are employed in the manufacturing of lightweight and durable components, contributing to overall vehicle efficiency and performance. As these industries continue to evolve, the innovative applications of epoxy resin will undoubtedly play a pivotal role in shaping modern manufacturing processes.

Innovative Applications of Epoxy Resin Across Various Sectors

Sustainability in Manufacturing: China's Commitment to Eco-Friendly Practices

In recent years, China's commitment to sustainability in manufacturing has become increasingly evident, particularly in the production of premium casting epoxy resin. By integrating eco-friendly practices and advanced technologies, Chinese manufacturers are not only enhancing product quality but also minimizing environmental impact. This movement towards greener manufacturing methods reflects a broader trend in the industry, where sustainability is becoming a vital consideration for consumers.

When selecting epoxy resin products, consider opting for brands that prioritize sustainability in their production processes. Look for certifications that indicate eco-friendly practices, such as low volatile organic compound (VOC) emissions. Additionally, familiarize yourself with the brand's sourcing policies, as responsible sourcing of raw materials plays a significant role in reducing the ecological footprint of the finished product.

Another essential tip is to explore the recycling options available for epoxy resin waste. Manufacturers dedicated to sustainability often provide guidance on how to properly dispose of or repurpose leftover materials. Engaging with brands that offer take-back programs or upcycling opportunities can further support environmentally responsible consumption, making your use of casting resin a part of the solution rather than the problem.

100% Mercury Free

All of Hapco's formulations are completely free of Mercury.

50 Year Track Record

Hapco has been in business for over 50 years!

*NOTICE* Hapco will be will be closed on Monday, May 26th, in observance of Memorial Day. |

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |