Category Archive: Liquid Plastics

The Disaster and Its Aftermath In our previous article, we discussed the tragic June 18, 2023 implosion of OceanGate’s Titan submersible that claimed the lives of five individuals during their descent to the Titanic wreckage. We explored how improper material selection can lead to catastrophic failures and emphasized the critical importance of choosing the right […]

Resin coatings are extremely useful in commercial and industrial settings and even in the art world. Resins are commonly used to coat surfaces like concrete floors or countertops, create high-gloss finishes, and make repairs. Two of the most common resins are epoxies and polyurethanes. Generally, epoxies are rigid, while polyurethanes will typically be more elastic. […]

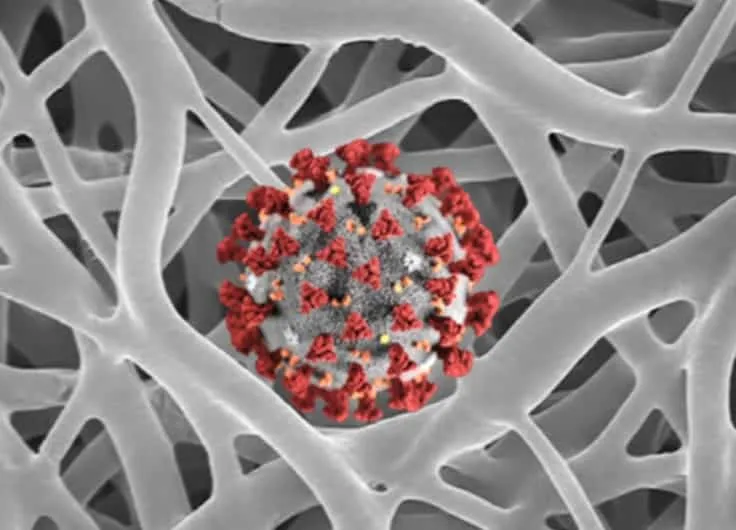

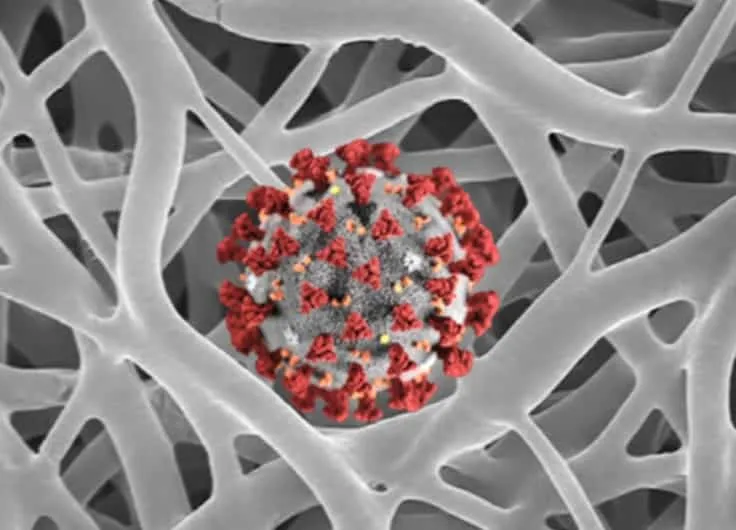

Filters are an essential component to entire industries, manufacturing facilities, processes, and in some cases, the end products themselves. Filters are enabling the tools and devices that are essential to defeating this invisible enemy we are now facing: Covid-19.

Part 2: Casting the Unicorn In part 1 of this how-to guide, we showed you how we created the silicone mold using Hapsil™ 360. In part 2, we will go through the steps and materials needed to cast a water clear part out of Ultraclear™ 480N-40, using Hapco’s X-80 Molding Chamber and X-Vac™ Chamber. Ultraclear™ […]

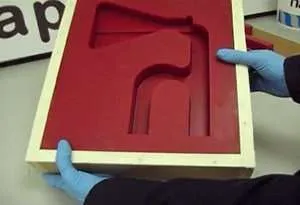

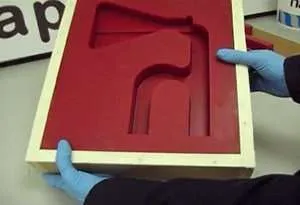

In this article, we show you step by step, how to duplicate a complex pattern using Hapco’s high performance materials and equipment.

There are many specialty resins that are formulated for highly-engineered applications, and because of their unique chemistries, they have a thicker viscosity than other products, making them a bit trickier to process. This article offers helpful advice to those who need to process a thicker viscosity resin in order to meet a wider range of requirements for their parts.

Achieving clear, bubble-free parts using clear epoxy or urethane is not impossible, but as anyone with experience will tell you, it’s not without its challenges either. The task can be even more daunting if the part possesses complex detail or undercuts, however with the right combination of materials, equipment, and expertise, attaining water-clear castings without […]

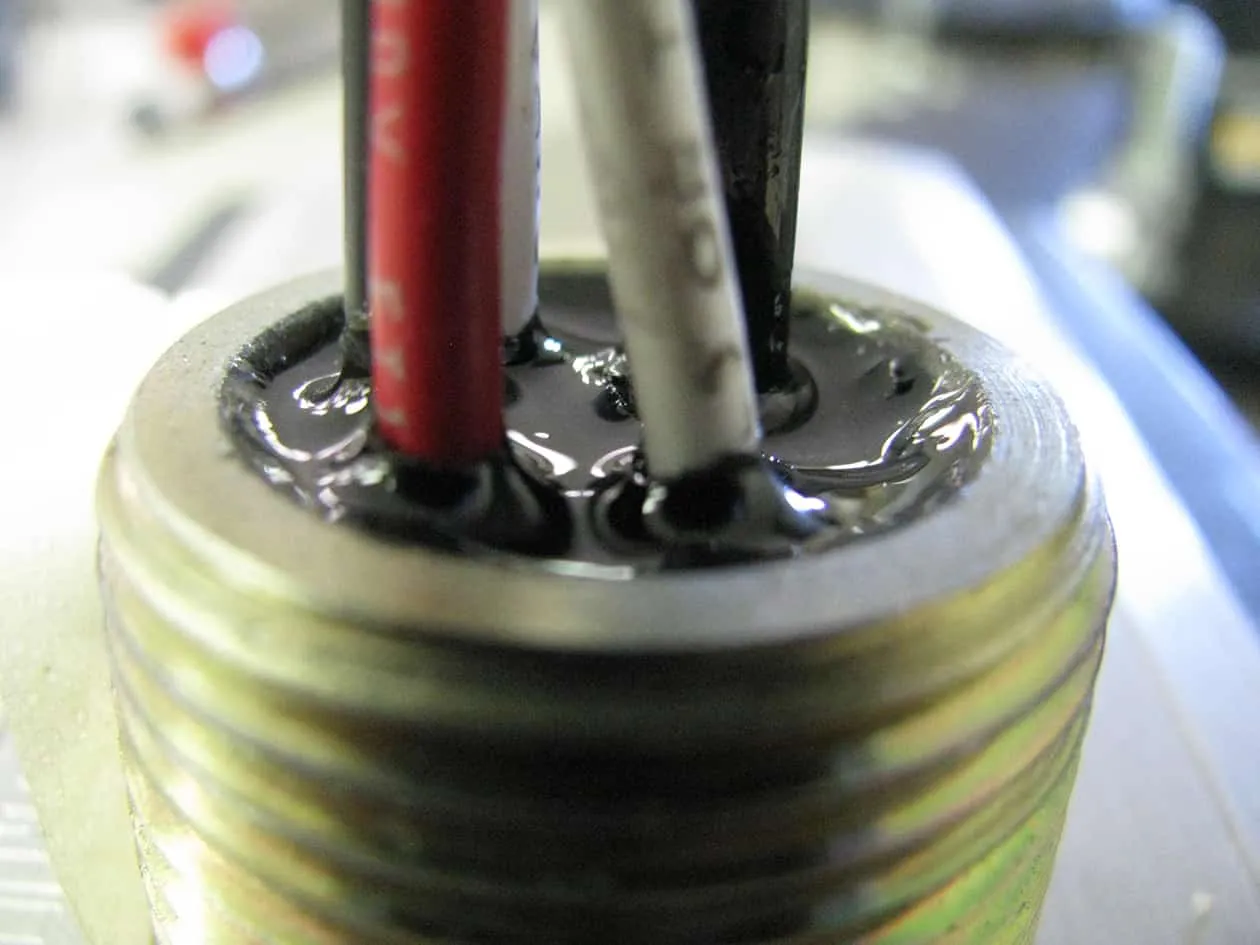

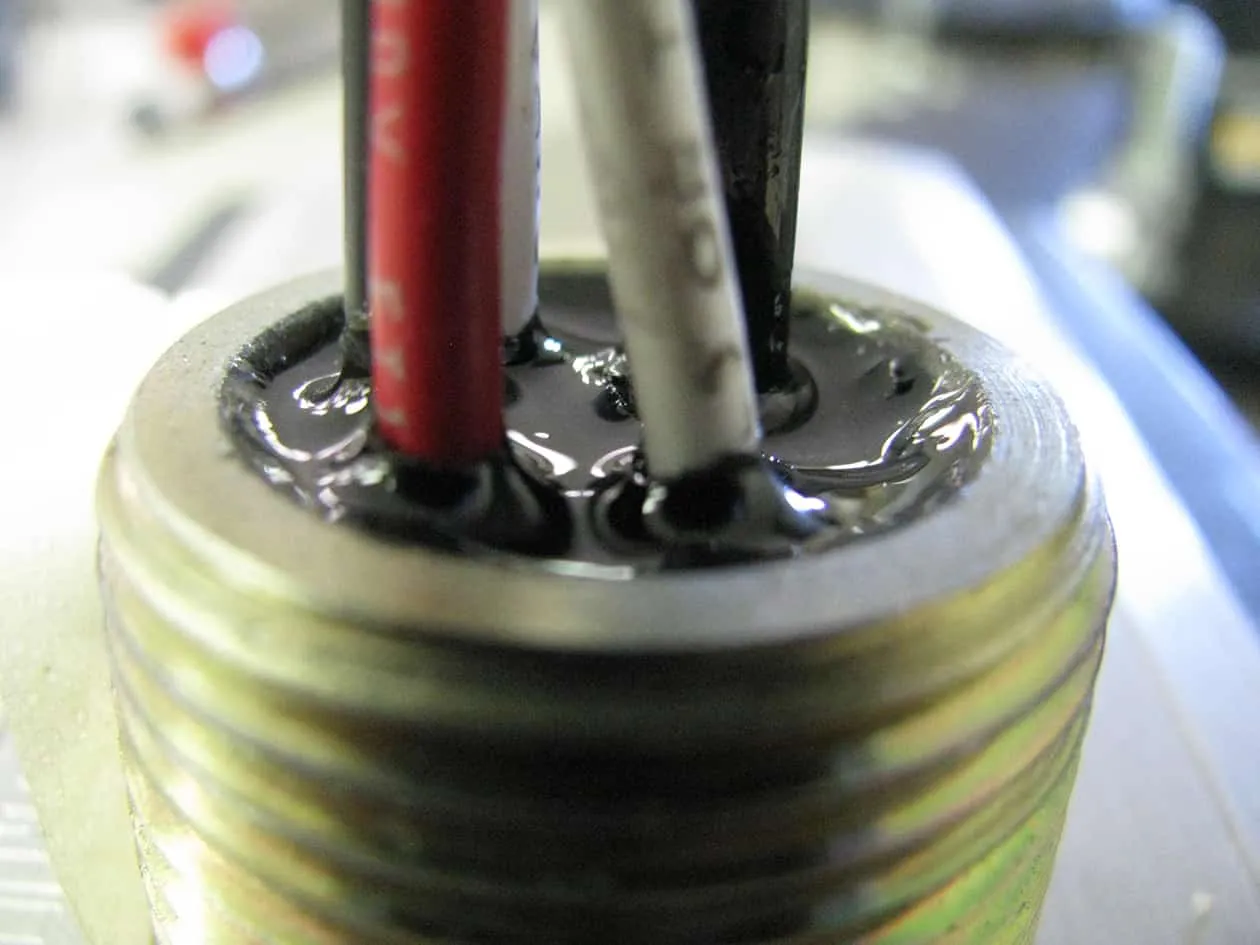

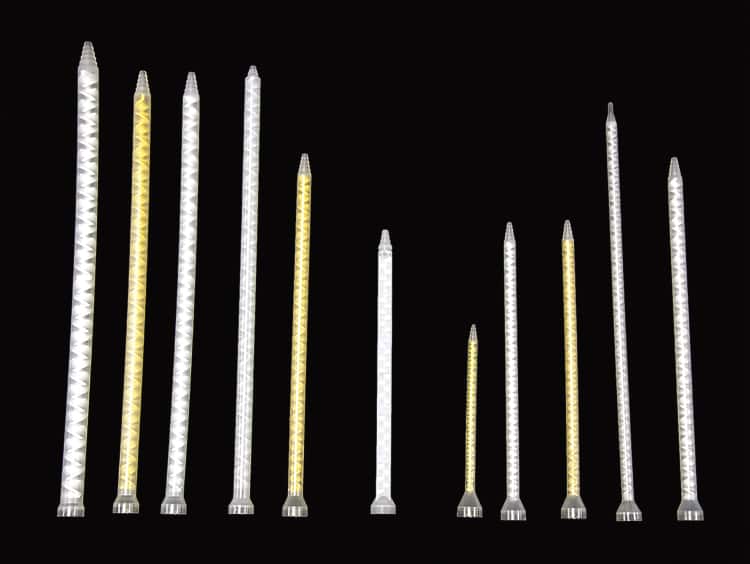

In our previous post, we discussed the application of potting and encapsulating using urethanes and epoxies. When choosing the proper urethane or epoxy for an electrical application, there are some important considerations to keep in mind. In this article, we will discuss those considerations and how they apply to the world of urethanes and epoxies. […]

What is RoHS Compliance? The European Union set forth the RoHS (Restriction of Hazardous Substances) Directive to establish environmental guidelines and legislation to reduce the presence of six (6) materials deemed hazardous to the environment. To comply, products entering the EU must not have a homogeneous presence of these materials above the following levels by […]

Enacted in 1989 and amended most recently in 2006, The Toxics Use Reduction Act(TURA) requires Massachusetts companies that use large quantities of specific toxic chemicals to evaluate and plan for pollution prevention opportunities, implement them if practical, and annually measure and report the results. Learn more. TURA Reporting & Fees Each company considered a Large […]

Q. What is the difference between vacuum degassing and pressurizing? A. Vacuum de-gassing expands the air trapped during mixing or pouring, causing the bubbles to grow, rise to the surface, and in most cases, release. After a period of time the amount of trapped air decreases. The material’s viscosity and surface tension will determine how […]

Polypropylene (Impact, heat and flex) Polypropylene has a tensile strength of 4,500-6,000 psi, an elongation of 1-600% and an izod impact of 2.2-no break at all. For the best simulator of these properties, Hapco would recommend using Hapflex 666 or Hapflex 671. Both products come in slow and fast gel times and are available in […]

Potting consists of immersing the part or assembly in a liquid resin, and then curing it. Although often confused for each other, potting is different from encapsulation in that it retains the shell that is used to contain the thermoset resin while it’s curing. Encapsulation involves building a mold or frame around an object, e.g., […]

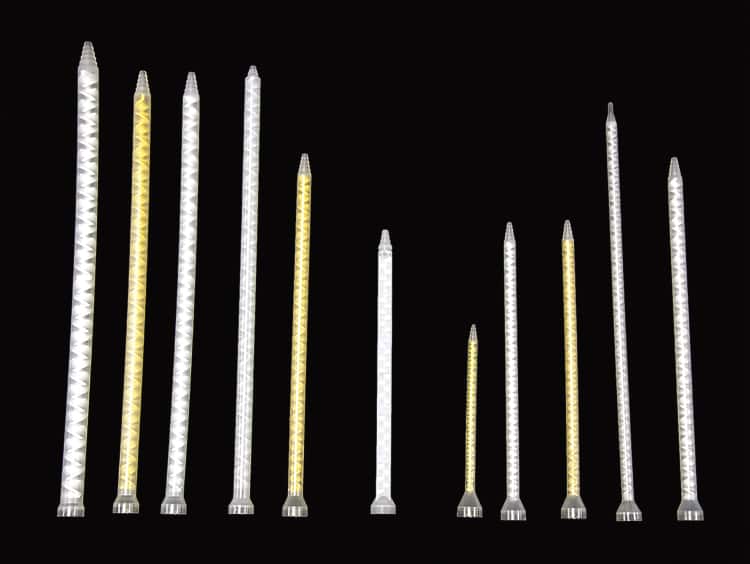

“There are so many different static mixers, which one is right for my application?”, is a common question asked by our customers. The answer, as with many aspects to liquid molding, is complicated and should ultimately involve testing by the user within their application; however, there are some basic differences in the static mixer, which […]

Clear part with an uncured surface. If I had to come up with a list of the most common issues our customers call us about, along with air bubbles, a sticky surface on their clear castings would be at the top. My first question to them is always: Are you using silicone? In 95% of […]

This video will teach you how to create a mold with a high performance surface material and a machinable, low cost backup, which in this case is Hapco’s Fill-Its/Haprez combo. The reason for creating a mold like this is to cut down on the thickness of the Hapflex 668, a high performance material, which can be expensive. […]