Category Archive: Silicone Rubbers

Part 2: Casting the Unicorn In part 1 of this how-to guide, we showed you how we created the silicone mold using Hapsil™ 360. In part 2, we will go through the steps and materials needed to cast a water clear part out of Ultraclear™ 480N-40, using Hapco’s X-80 Molding Chamber and X-Vac™ Chamber. Ultraclear™ […]

In this article, we show you step by step, how to duplicate a complex pattern using Hapco’s high performance materials and equipment.

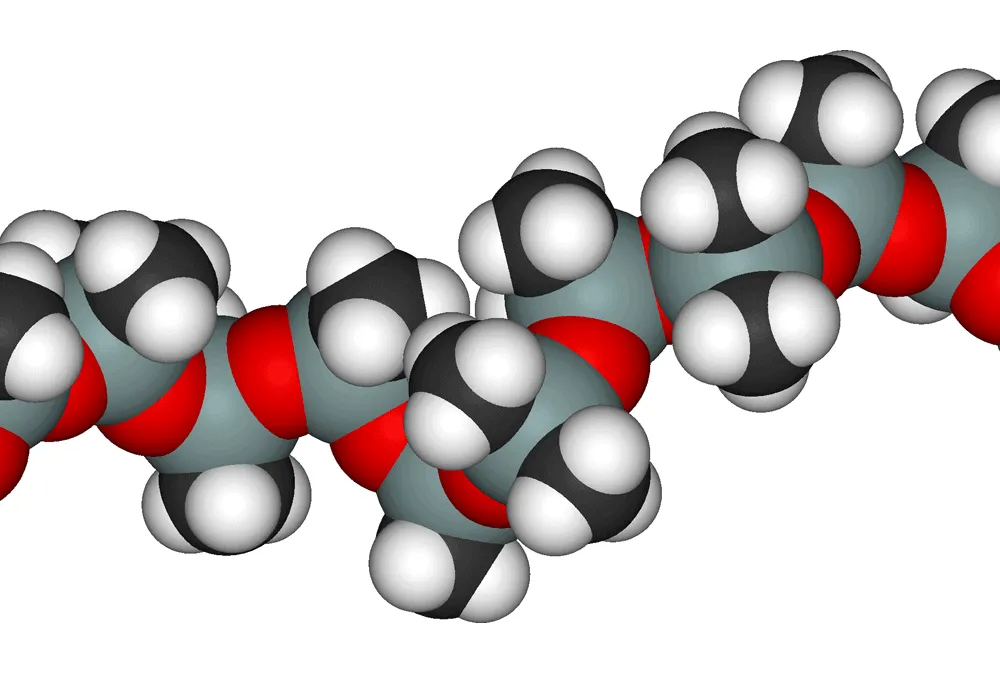

Silicones are commonly used in the liquid molding process to make molds and parts. Understanding the differences between the different types of silicone can be helpful before deciding what to buy for your application.

Clear part with an uncured surface. If I had to come up with a list of the most common issues our customers call us about, along with air bubbles, a sticky surface on their clear castings would be at the top. My first question to them is always: Are you using silicone? In 95% of […]

The liquid molding, or the resin casting process as it is typically referred to, lets designers produce high-quality plastic parts economically in low volumes. Any shape that can be machined or injection molded can be cast, however, liquid molding becomes most attractive when part geometry poses design restrictions for traditional processes. Varying wall thicknesses, internal […]

A few months back, we discussed the differences between Liquid Molding and Injection Molding and described when each method is appropriate. As a follow up, we thought it would be important to focus on Liquid Molding and to discuss some of the tooling options as well as the advantages and disadvantages to using each. Aluminum […]